In industrial manufacturing, downtime can be devastating. A single machine failure can halt production, delay shipments, and cost thousands of dollars in lost revenue. That’s why preventative maintenance (PM) is no longer optional—it’s a smart investment that keeps equipment running smoothly, minimizes costly breakdowns, and saves companies serious money year after year.

1. The Cost of Downtime

Unplanned equipment failures often lead to:

- Production losses from halted operations

- Overtime labor costs to meet deadlines after repairs

- Rush orders for replacement parts or expedited shipping

- Missed customer commitments damaging reputation and future business

Studies show that unplanned downtime costs manufacturers hundreds to thousands of dollars per minute, depending on the industry. Preventative maintenance helps avoid these unexpected expenses.

"Preventive maintenance is the silent protector of productivity."

2. What is Preventative Maintenance?

Preventative maintenance involves scheduled inspections, servicing, and part replacements before equipment fails. Typical PM tasks include:

- Lubricating moving parts

- Checking electrical connections

- Replacing worn-out components

- Calibrating machines for optimal performance

By addressing small issues early, facilities prevent them from becoming costly breakdowns.

3. How Preventative Maintenance Saves Money

a) Extends Equipment Life

Routine care prevents excessive wear and tear, helping machines last longer and delaying expensive replacements.

b) Reduces Emergency Repair Costs

Emergency fixes often involve higher labor rates, overnight shipping, or entire system replacements. PM minimizes these urgent scenarios.

c) Improves Energy Efficiency

Well-maintained equipment uses less energy, cutting utility bills over time.

d) Prevents Production Delays

By avoiding unplanned downtime, facilities keep output steady and customers happy—protecting revenue streams.

4. Real-World Example: Savings in Action

Consider a manufacturing facility with a critical piece of equipment worth $250,000. One unexpected breakdown could cost:

- $20,000 in repairs

- $50,000 in lost production

- $5,000 in rush shipping

A preventative maintenance plan costing just $8,000 per year could prevent this scenario entirely—saving tens of thousands annually.

5. Additional Benefits Beyond Cost Savings

- Increased Safety: Equipment failures can cause workplace injuries; PM reduces these risks.

- Regulatory Compliance: Routine checks help meet OSHA or industry standards.

- Improved Equipment Performance: Machines run at peak efficiency, improving product quality.

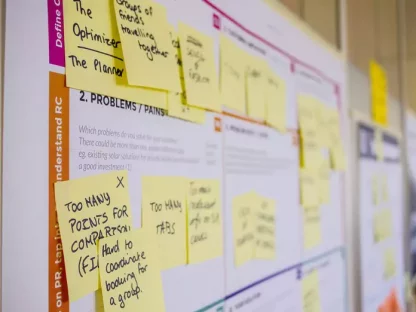

6. Implementing an Effective PM Program

A successful preventative maintenance plan should include:

- Regularly scheduled inspections based on equipment usage

- Maintenance logs to track completed tasks and upcoming needs

- Predictive analytics using IoT sensors for early fault detection

- Trained staff to perform and document maintenance work

Conclusion

Preventative maintenance is one of the smartest investments an industrial facility can make. By spending a fraction of the cost upfront, manufacturers save thousands each year while extending equipment life, reducing downtime, and keeping production on track.

The choice is clear: maintain now or pay more later.